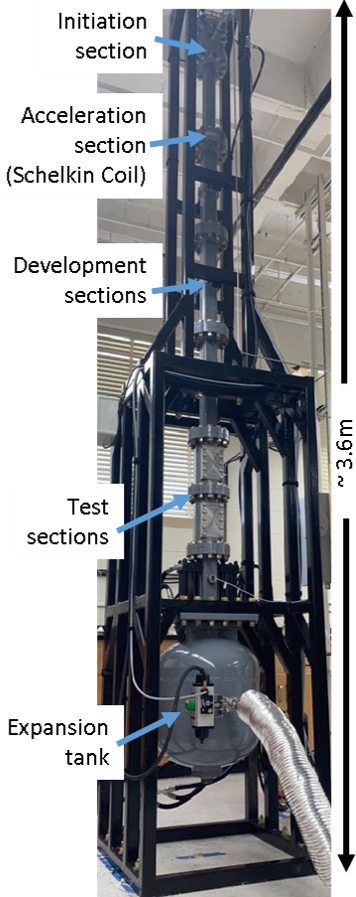

1. High-Speed Microscopy Shadowgraph

High-resolution imaging is achieved utilizing pulsed backlight illumination. The measurement volume is determined by both the focal plane and the depth of field of the imaging system. This method is versatile, being unaffected by the shape or material (whether transparent or opaque) of the particles, and enables the examination of sizes down to the micro-scale when coupled with a suitable optical system.

Equipment:

– Phantom T3610 with a K2 – Long Distance Microscope (1 million frames per second)

- The backlit illumination utilizes a high-speed laser at 532 nm with a diffuser plate.

- 120 kHz Ultrasonic Atomizer

- Spray Characterization SUJ11

– Specialized Imaging – SIMX16 with a K2 – Long Distance Microscope (1 billion frames per second)

- The backlit illumination utilizes a Silux burst laser at 643 nm.

- Monodisperse Dispenser 40 um – 15Khz

- High magnification (x3.5) 170 um acetone droplet breakup.

– Continuous 18 W Coherent Verdi C18

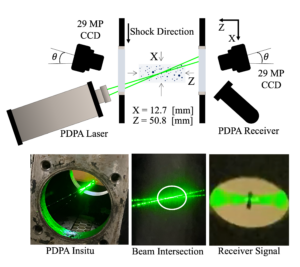

– Phase Doppler Particle Analyzer (PDPA) – (up to175 MHz)

The PDPA provides accurate and reliable flow velocity and particle size data at a low signal-to-noise ratio. It can detect particle diameter from 0.5 – 150 um.

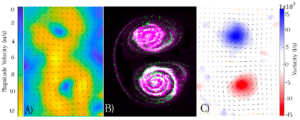

– Particle Imaging Velocimetry (PIV) and Planar Laser-Induced fluorescence (PLIF)

PIV imagery from TSI instruments

- Full frame CCD Cameras (x2) 29 [MP] and APS-C frame (x1) 4[MP] with 5.5 [um] per pixel and QE of 50% at 510 [nm].

- NanoPIV 200 [mJ] at 532 [nm] and 40 [mJ] at 266 [nm].

- Custom Laser Sheet Forming Optics

– PIV imagery from LaVision

- APS-C fImager CX-25 (x2) 25 [MP] with 2.7 [um] per pixel and QE of 70% at 510 [nm].

- NanoPIV 200 [mJ] at 532 [nm].

- Laser Sheet Forming Optics.

– Planar Laser Mie Scattering

High-resolution [29 MP] imaging of droplets interacting with shock and detonation waves.